Deyma · Decontamination and environment

Separators

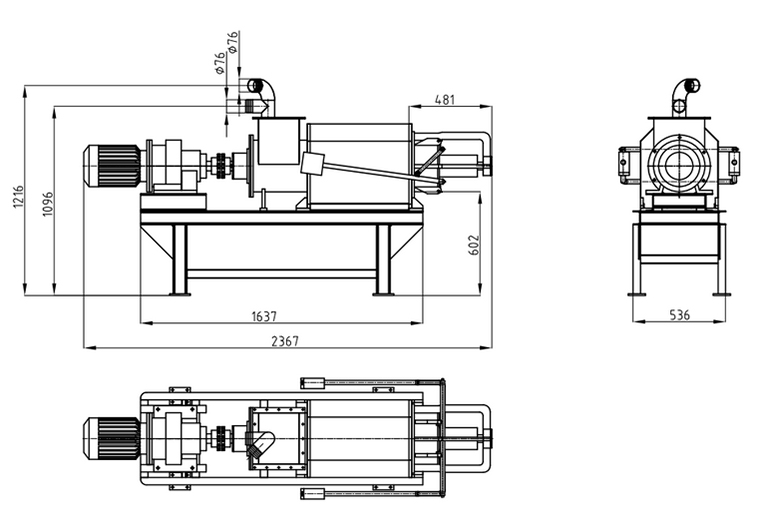

Solid - Liquid Separators TZ-200 and TZ-280

Presentation

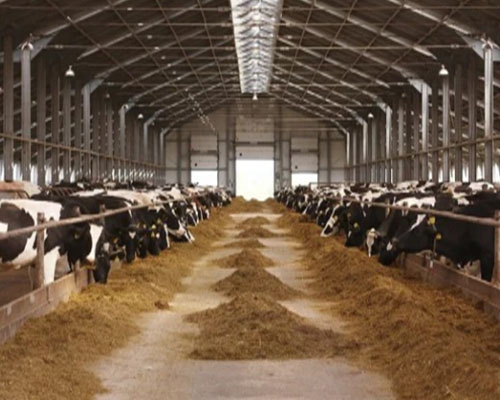

The solid-liquid separation equipment for cow slurry begins its process by installing a submersible pump with a grinder in the septic tank or in the slurry accumulation pool, which sends it to the separator feed inlet. It is an advanced spiral extrusion mechanical dewatering equipment.

In the machine’s sieve drum, the liquid part passes through the screen filters or sieve until it reaches the overflow hose while the solid part is squeezed and separated through the pressure of the steel auger shaft. stainless steel placed inside the screen. The screw continuously pushes the cow manure forward until it exits through the ejector nozzle, transformed into a fine, smooth and

homogenized manure optimal for cow bedding or organic fertilizer for other animals.

This separator is made up of a feeding inlet, a central extrusion body with an auger, screen filters in mild iron and high-resistance 304 stainless steel, anticorrosive and wear-resistant, with a vibration motor, a reduction motor, a suction, distribution cabinet, electrical panel, discharge device, overflow and outlet pipes, shelf, transport wheels and multi-layer anticorrosive paint. The solid-liquid separation speed is fast and easy to operate; simply pressing the start and stop button for its operation.

In general terms, the water content of fresh cow slurry can reach up to 80% and 90%. The moisture content of the separated manure is between 50 and 60%. This already partially dehydrated manure is suitable for transport.

The resulting liquid is used as a liquid fertilizer to be applied directly to the fields or diluted with irrigation water. It facilitates its pumping and fertigation through irrigation sprinklers or injection into the earth, but with one more advantage, that the same amount of slurry required for its discharge on farmland as required by law for compliance with environmental regulations, requires 20% less unloading area. This 20%, which is the percentage of nitrogen decreased in the separation, reduces the dimension of the accumulation ponds, no crusts are generated that solidify the surface of the ponds, there is less risk of breakage, leaks, savings in maintenance costs and of transport as the transport volume is smaller and the load is easier. And another socially and environmentally important advantage is the undoubted reduction in odor.

The separation allows obtaining up to 30%-35% of dry matter from the separated solid and reduces the total nitrogen by 20%, 50% of the total phosphorus and 20% of the total potassium that the slurry had before separation.

Advantages

- High performance.

- Very cheap price.

- Low maintenance cost.

- Low power consumption.

- Maximum use and value of the separated fractions.

- Tailor-made financing.

- Easy commissioning.

- Simple operation.

- Automated control system.

- Long useful life.

- Little noise.

Benefits

- Save time and money on labor.

- They save thousands of euros on the purchase of the bed for the holidays (sand, sawdust, sawdust+carbonate, straw and rubber+padding).

- They save money in the volume and discharge of the slurry and maintenance of the accumulation ponds.

- Value of compost not used for bedding.

- Separated liquid, useful for drip irrigation or fertigation.

- Reduction of mastitis and leg disease in cows (Savings in veterinary and medicines).

- Odor reduction.

- Reduction of greenhouse gas emissions (Methane, C02 and other gases).

Technical Characteristics

Models | TZ-200 | TZ-280 |

|---|---|---|

Voltage | 380 V | 380 V |

Power | 4 kw | 5.5 kw |

Extent machine(mm) | 2200 * 610 * 1350 | 2400 * 800 * 1300 |

Machine weight | 510 kg | 680 kg |

Capacity | 10 – 15 M³/H (depending on subject cousin)

| 20 – 25 M³/H (depending on subject cousin) |

Set screw speed | 49 r/min | 49 r/min |

Sieve (filter) diameter | 200 mm | 280 mm |

Inlet diameter | 76 mm | 76 mm |

Overflow hole diameter | 76 mm | 76 mm |

Drain pipe diameter | 110 mm | 110 mm |

Machine material | Ductile iron and 304 stainless steel | Ductile iron and 304 stainless steel |

Pressure screw material and sieve (filter) | 304 stainless steel | 304 stainless steel |

Special design | Movable with 4 wheels | Movable with 4 wheels |

Tube inlet | Si | Si |

Inlet pipe length | 10 m | 10 m |

Inner diameter of the sieve (filter) | 200 mm | 280 mm |

Inner sieve mesh | 500,750 or 1000 micron optional (depending on raw material) | 500,750 or 1000 micron optional (depending on raw material) |

Inner length of sieve (filter) | 580 mm | 600 mm |

Warranty | 1 year | 1 year |

After sales service | Forever | Forever |

Date of Delivery | 45 days | 45 days |

Spare Parts

Models | TZ-200 | TZ-280 |

|---|---|---|

Set screw length | 1500 mm | 1560 mm |

Pump weight | 70 kg | 70 kg |

Screw weight | 50 kg | 63 kg |

Sieve weight (filter) | 14 kg | 17 kg |

Product Structure

Complete Team

- TZ-200 and TZ-280 solid-liquid separating machines

- Sieve protector in stainless steel

- Submersible pump with macerator

- Slurry inlet pipe

- Electricity cupboard

Application Scenarios